Offshore Wind

Leask Marine remains at the forefront of the offshore marine renewable industry, recognised as one of the leading experts in renewable energy.

The company has been actively involved in nearly every major offshore renewable project across Northern Europe.

In particular, the offshore wind sector has seen a significant presence of Leask Marine, supporting global renewable energy utility companies such as Ørsted, ScottishPower, Vattenfall, E.ON, EnBW, edp, and EDF. To date, the company has contributed to operations on over 30 offshore wind farms throughout Europe.

Project in mind? Let’s Talk!

- +44 (0)1856 874 725

- info@leaskmarine.com

Moray West Offshore Wind Farm

Moray West Offshore Wind FarmLeask Marine were contracted by our project partners Nexans to perform the nearshore diving works and post cable pull-in at the landfall site. This involved the recovery of pre-laid concrete mattresses at each HDD exit point, the recovery of the bellmouths, and the duct seal installations.

The Moray West Wind Farm houses 60 turbines with 2 offshore substation platforms to power 1.3million homes. Moray West is part of the UK portfolio of Ocean Winds, the joint venture between EDP Renewables and ENGIE formed to develop, build, own and operate offshore wind farms. Moray West stands alongside the operational 950MW Moray East wind farm, also operated by Ocean Winds, and in a few years will be joined by the Caledonia project to complete the trio of Ocean Winds wind farms in the Moray Firth.

Belwind Offshore Wind Farm

Belwind Offshore Wind FarmLeask Marine was contracted by our project partners Jan De Nul and the University of Ghent to carry out the installation of screw auger anchors for two different aquaculture lines, one for seaweed and one for oysters, in the Belwind Offshore Wind Farm, Belgium.

This involved Leask Marine’s MV C-Odyssey and the Leask Marine specially designed and fabricated auger drill rig and anchors to deploy the aquaculture lines.

Belwind is Parkwind’s first wind energy project and one of Belgium’s first offshore wind farms, located 49 km from shore in the North Sea. Belwind is one of the most distant offshore wind farms in this Belgian development zone.

Leask marine supported their client DCN Diving with a Dive Support Vessel for diving operations at the Kincardine Offshore Wind Farm.

Kincardine stands as the largest floating offshore wind farm installed on a semi-submersible foundation. The project is located 15 km off the coast of Aberdeen, in waters ranging from 60 to 80 m deep, and it features five WindFloat T units hosting 9.5 MW turbines.

Ormonde Offshore Wind Farm

Ormonde Offshore Wind FarmLeask Marine supported their client, Ambipar Response Ltd, in successful marine salvage operations, Ormonde OWF Work to recover the blades and rotor of a wind turbine from the seabed, following an incident during planned maintenance.

Ormonde Offshore Wind Farm is located in the Irish Sea, around 10km from the coast at Barrow-in-Furness in the North-West of the UK.

Codling Offshore Wind Park

Codling Offshore Wind ParkLeask Marine supported their client Akrocean with a Lidar Buoy Recovery & Installation, at the Codling Offshore Wind Park in Ireland

Codling Wind Park is Irelands largest Phase One offshore wind farm in development in the Irish Sea, approximately 13-22 kilometres off the County Wicklow coast, between Greystones and Wicklow Town.

It will generate 1,300 MW of electricity from 60 or 75 wind turbines, enough to power 1.2 million Irish homes, nearly half of all Irish dwellings. When operational, Codling Wind Park will deliver over 26% of Ireland’s 2030 grid connected offshore wind targets. It will also help Ireland achieve its target of generating 80% of its electricity from renewable energy by the same year.

The project is a 50/50 joint venture between Fred. Olsen Seawind and EDF Renewables. Both companies are leading developers, owners and operators of renewable energy assets, with many years of global experience in the renewable energy and offshore wind sector.

London Array Offshore Wind Farm

London Array Offshore Wind FarmThe Leask Marine team were contracted by London Array Offshore Wind Farm for a three-month campaign of works at the Moray East Offshore Wind Farm. The project used a number of Leask Marine resources with the supply of the C-Odyssey, line-boats, and full diving spread including chamber and LARS.

The scope of works included Diver Supported Cable Protection System Cleaning, the installation of Dynamic Bend Stiffeners to the J-Tubes, together with R&D instrumentation installation works.

Moray East Offshore Wind Farm

Moray East Offshore Wind FarmThe Leask Marine team were contracted by NKT AB for a six-month campaign of works at the Moray East Offshore Wind Farm. The project used a number of Leask Marine resources with the supply of the C-Fenna, C-Spartan, line- boats, and full diving spread including chamber and LARS, and airlift dredging. The scope of works included the nearshore airlift dredging for laying 3no. HDD pipes, preparing the Bellmouths for the cable pull-ins, pull though the messenger wires, and post pull in works including kennel installations and dive surveys.

Hornsea 03 Offshore Wind Farm

Hornsea 03 Offshore Wind FarmLeask Marine were engaged by AMS Trenchless Solutions and by Jan De Nul for 4No. HDD project works at Hornsea 03 Offshore Wind Farm, which is owned and run by Ørsted.

The 2024 and 2025 campaigns focused on the installation of four ducts, completing the overall nearshore scope for the HOW3 project. Leask Marine’s responsibilities included managing and executing all nearshore operations, JUB (Jack-Up Barge) management and coordination, and providing diving support as required. Our team ensured a safe and efficient operation for the recovery of the drill string to the JUB deck, duct handover and storage, duct tow to site, pigging operations, rock bag installation. Leask Marine delivered the full suite of Nearshore Support Operations, including shore side set-up & support, mooring operations, diving operations, making the HDD exits available, removal and replacement of rock bags, flange and bell mouth diving operations, pre-rigging of the bellmouth plug, general maritime assistance, including crew transfers, emergency vessel cover, and full support for daily offshore operations.

The team also performed a number of Multibeam Echo Sounder surveys (MBES) surveys throughout the campaign for both contractors

The Hornsea 3 (HOW3) project will be the largest offshore wind farm in the world, expected to generate enough renewable energy to meet the average daily needs of over 3 million UK homes—a milestone Leask Marine is proud to help deliver.

Hornsea 01 Offshore Wind Farm

Hornsea 01 Offshore Wind FarmLeask Marine were engaged by Fugro GB Marine for project works at Hornsea 01 Offshore Wind Farm, which is owned and run by Ørsted.

The MV C-Fenna was contracted for the recovery & deployment of Wave Buoys to support Fugro’s Engineering servicing & maintenance team for routine maintenance works on wave buoys at the Race Bank OWF.

Westermost Rough Offshore Wind Farm

Westermost Rough Offshore Wind FarmLeask Marine were engaged by Fugro GB Marine for project works at Westermost Rough Offshore Wind Farm, which is owned and run by Ørsted. The MV C-Fenna was contracted for the recovery & deployment of Wave Buoys to support Fugro’s Engineering team for routine maintenance works on buoys at the WMR OWF.

Race Bank Offshore Wind Farm

Race Bank Offshore Wind FarmLeask Marine were engaged by Fugro GB Marine for project works at Race Bank Offshore Wind Farm, which is owned and run by Ørsted. The MV C-Fenna was contracted for the recovery & deployment of Wave Buoys to support Fugro’s Engineering team for routine maintenance works on buoys at the Race Bank OWF.

Borssele 1 and 2 Offshore Wind Farm

Borssele 1 and 2 Offshore Wind FarmLeask Marine Ltd were contracted by Fugro GB Marine Ltd for project works at Borssele 1 and 2 Offshore Wind Farm, which is owned and run by Ørsted (Formally DONG Energy).

The Leask Marine vessel the MV C-Fenna was contracted for the deployment of 10 x seabed frames/buoys plus grab samples at each location across the Borssele 1 and 2 Offshore Wind Farm, in the Netherlands.

Leask Marine Ltd were contracted by Multraship Towage & Salvage for project works at Borssele 1 and 2 Offshore Wind Farm, which is owned and run by Ørsted (Formally DONG Energy).

The Leask Marine vessel the MV C-Fenna was contracted loading a wavescan buoy at Flushing, sailing out to Borsele OWF, and placing in the exact position determined by the client.

Walney Extension Offshore Wind Farm

Walney Extension Offshore Wind FarmLeask Marine Ltd were contracted by Deepocean 1 UK Ltd for project works at Walney Offshore Wind Farm extension project which is owned and run by Ørsted (Formally DONG Energy).

Leask Marine’s MV C-Fenna team were on Anchor Handling and tow assist for the Maersk Connector, that was on long term charter to DeepOcean 1 UK Ltd supporting offshore renewable power transmission projects.

This project was specifically on the Walney Offshore Wind Farm extension project that is located in the Irish Sea 19km off the Walney Coast in Cumbria and covers an area of 145km².

![]()

Burbo Bank Offshore Wind Farm

Burbo Bank Offshore Wind FarmLeask Marine Ltd were contracted by Mojo Maritime for project works at Burbo Bank Offshore Wind Farm which is owned and run by Ørsted (Formally DONG Energy).

The project required the Leask Marine vessel MV C-Odyssey to perform anchor transportation from Ardrossen to Liverpool and then anchor handling operations in the wind farm.

West of Duddon Sands Offshore Windfarm

West of Duddon Sands Offshore WindfarmLeask Marine's C-Fenna successfully completed supporting Irish Sea Contractors who were performing subsea cable inspections in the West of Duddon Sands Offshore Windfarm. The West of Duddon Sands Offshore Wind farm is a joint venture between DONG Energy and ScottishPower Renewables.

The Wind Farm is located approximately 14km from the nearest coast off Walney Island, Cumbria and covers an area of approximately 66km2. The wind farm comprises of 108 wind turbine generators, each with a capacity of 3.6MW giving a total capacity of 389MW. Each wind turbine generator is connected by submarine cables to an offshore substation inside the wind farm and from there via two 155kV submarine cables to the shore, by way of a landfall near Middleton in Lancashire, and National Grid transmission system.

East Anglia ONE Offshore Wind Farm

East Anglia ONE Offshore Wind FarmLeask Marine were engaged by ABCO Marine supporting their client Fugro 1200 offshore drilling unit at East Anglia ONE Offshore Wind Farm, which is owned and run by Scottish Power Renewables. The MV C-Fenna was contracted for routine support works such as anchor handling and transportation between port and the Fugro 1200.

East Anglia THREE Offshore Wind Farm

East Anglia THREE Offshore Wind FarmLeask Marine Ltd were contracted by Dutch Marine Contractors for Fugro Norway AS project works at East Anglia THREE Offshore Wind Farm, which is owned and run by ScottishPower Renewables (Iberdrola Renovables Energia SA).

The Leask Marine vessel the MV C-Fenna was contracted for Fugro Norway AS and Scottish Power Renewables for the Recovery & Deployment of a large Wind Lidar buoy in East Anglia 3 Offshore Wind Farm.

Rampion Offshore Wind Farm

Rampion Offshore Wind FarmLeask Marine Ltd were contracted by Seatech Commercial Diving Services Ltd for project works at Rampion Offshore Wind Farm extension project which is owned and run by E-ON.

The Leask Marine vessel the MV C-Fenna was used as a Dive Support Vessel for maintenance operations and assisting a fibre optic cable installation. Seatech chartered the MV C-Fenna and other equipment for their dive support operations for their client Global Marine Group on the Rampion Offshore Wind Farm, where both teams are working out of Shoreham by Sea.

Leask Marine Ltd were contracted by Caledonian Towage on behalf of their client Babcock International for the deployment of a large Lidor buoy on the proposed site of The European Offshore Wind Deployment Centre (EOWDC), Scotland’s largest offshore wind test and demonstration facility which is being developed by Vattenfall-owned Aberdeen Offshore Wind Farm Limited.

Leask Marine loaded the Lidor buoy at Nigg Energy Park and transported and deployed it off Aberdeen as the specified position.

![]()

Baltic 1 Offshore Wind Farm

Baltic 1 Offshore Wind FarmLeask Marine Ltd were contracted by Offshore Projects Unique Solutions (OPUS) Marine GmbH to support their operations from Rostock, Germany, with the MV C-Odyssey performing anchor handling support activities for the MV Valdemat.

Leask Marine Ltd were contracted by Baltic Taucherei- und Bergungsbetrieb Rostock GmbH to support their operations with Leask marine's MV C-Odyssey acting as a Diving Support Vessel for their diving operations in the Baltic 1 Offshore Wind Farm.

![]()

Baltic 2 Offshore Wind Farm

Baltic 2 Offshore Wind FarmLeask Marine Ltd were contracted by Dalby Offshore Services to support their managed accommodation barge the ‘ASV Pioneer' is assisting in splicing cable works on the Baltic 2 Windfarm on behalf of their client Norddeutsche Seekabelwerke GmbH. Leask Marine's MV C-Odyssey works included towage and anchor handling for the ASV Pioneer.

The MV C-Odyssey returned later in the year to Dalby Offshore services in supporting the ASV Pioneer as she departed Rostock under tow of the tugs including the MV C-Odyssey to return to the Baltic 2 wind farm to support a 2nd cable splice for their client NSW. This operation was closer to shore than the previous one and in shallower waters of about 7 metres depth.

![]()

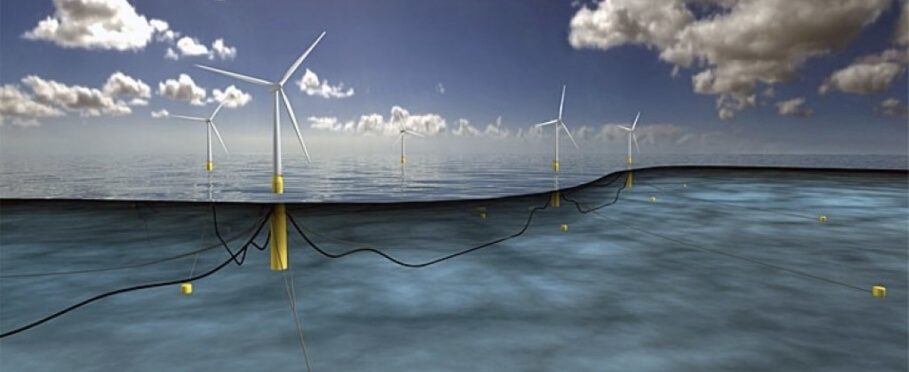

Statoil Hywind Scotland Offshore Floating Wind Pilot Park

Statoil Hywind Scotland Offshore Floating Wind Pilot ParkLeask Marine Ltd were contracted by Metocean Services International (pty) Ltd for project works in Hywind SCOTLAND pilot park (uk), off Aberdeenshire.

Metocean Services International (pty) Ltd required Leask Marine's vessel the MV C-Odyssey for an instrumentation deployment & recovery program ahead of Statoil world's first floating wind farm build.

Partrac Ltd also required Leask Marine's vessel the MV C-Odyssey to perform Wavebuoy deployment works on site ahead of build operations.

Beatrice Offshore Wind Farm

Beatrice Offshore Wind FarmLeask Marine's C-Fenna & C-Odyssey recently completed multiple Buoy Recovery & Redeployment works for Sealite United Kingdom Ltd located in and around the Beatrice Offshore Windfarm.

Leask Marine were contracted to provide the marine services associated with the recovery of the TRIDENT-3000 and Waverider buoys to deck where Sealite personnel carried out essential maintenance activities on the buoy's before the vessel crew redeployed them on site. The water depths at the locations of the buoy's was approximately 60m.

Moray offshore renewables ltd (MORL)

Moray offshore renewables ltd (MORL)Leask Marine Ltd were contracted by Drace Infraestructures S.A. for project works in Moray Firth Offshore Renewables Limited (MORL)

Drace Infrastructures UK required Leask Marine's vessel the MV C-Odyssey to perform anchor handling, towing and mooring handling operations for the Barge Jan while working on the company's meteorological offshore mast structure in the Moray Firth. The 4no. 5tonne anchors were positioned and moved as required during operations.

Drace Infrastructures UK also required Leask Marine's vessel the MV C-Odyssey to perform the recovery of a lattice structure from the seabed at the base of the met mast foundation to their deck and return it to land. The vessel deployed 3no. 2 tonnes anchors in order for the vessel to hold in location for operations. The met mast measures wind conditions at the site ahead of the construction of the wind farms.

Inch Cape Offshore Limited (ICOL)

Inch Cape Offshore Limited (ICOL)Leask Marine Ltd were contracted by Drace Infraestructures S.A. for project works in Inch Cape Offshore Limited (ICOL) which is 100% owned by Red Rock Power.

The Rock bag deployment project required the Leask Marine vessel MV C-Odyssey to perform the deployment of 20no. 8 tonne rock bags surrounding the base of the Metrological Mast Installation Foundation in 47metres of water. The Vessel was on a 3-point mooring, anchors with 2no. 3tonnes anchors and 1no. 24 tonnes clump weight anchor system which was deployed in order for the vessel to hold in location for operations.

In 2025 Leask Marine’s MV C-Force supported Enshore and the Inch Cape Offshore Wind Farm by managing and executing Pre-Lay Grapnel Runs (PLGR) ahead of the installation of two export cables to the wind farm array.

The C-Force carried out over 80 kilometres of PLGR to ensure the seabed is completely clear of obstructions before future cable-laying operations. The PLGR route is pre-programmed into the vessel’s survey and navigation systems to enable precise execution.

Leask Marine deployed one of their grapnel trains comprising a flatfish grapnel, rennie grapnel, gifford grapnel, and a specially made spearpoint grapnel by the fabrication team to ensure the required depth was achieved on the first run.

MBES showing PLGR trail

The train was also integrated with a transponder USBL tracking system within a Stingray Acoustic Tow Line Positioning Grapnel. Operations were supported by Leask Marine’s CTV, the C-Spartan.

Gwynt y Môr offshore wind farm

Gwynt y Môr offshore wind farmLeask Marine Ltd were contracted by Mojo Maritime for project works at Gwynt y Môr offshore wind farm.

The project required the Leask Marine vessel MV C-Odyssey to deploy a large Lidor buoy at a fixed position within the wind farm.

The Leask team are experienced in a range of offshore wind marine contracting capabilities including:

- Offshore drilling & mooring solutions

- Rock anchoring

- Naval architectural & engineering design services

- Towing & mooring management & Handling

- Anchor management for cable laying vessel

- Equipment Deployment & recovery

- Module replacement

- Ladder module recoveries

- Anchor handling for cable laying barge

- Dive Support Vessel

- Subsea umbilical recovery & replacement

- Deploying & recovery of wave rider buoys

- Deployment & recovery of wave scan buoys

- Recovery & Deployment of Wind Lidar buoys

- Recovery of seabed ADCP frames

- Recovery & redeployment of Cardinal buoys

- Subsea Link cable support works

- ROV inspection

- Subsea sample grabs

- Drilling rig Towage

- Met Mast buoy recovery & deployment

- Profiler deployment & recovery

- Fibre optic cable laying

- Subsea cable-management concrete mattress laying

- Instrumentation deployment & recovery

- Rock armour placement

- Sub-structure removals & replacement

- Rock bagging

- Underwater welding & cutting

- Piling work

- Concrete mattress installation

- Hydraulic tooling including underwater chainsaws, drills and grinders

- Submarine cable installation

- Marine project management

- Plant hire

- Precast, reinforced & mass/in-situ concrete

- Coastal protection

- Fabrication works

- Concrete and grout replacement

- Scour protection

- Fitting anodes to piles or other sub-sea structures

- Fitting Dynamic Bend Stiffeners

- Subsea Asset painting

Our clients find that using Leask Marine’s multi-worker style vessels and operational hire equipment ensure excellent working platforms for a large range of working activities at a competitive rate. Leask has a great story to tell in this exciting supply chain, having already experience many success stories on operations, maintenance, array cables and substation project works in particular.

By visiting our site, you agree to our privacy policy regarding cookies, tracking statistics, etc.